Sludge Dewatering Screw Press Manufacturers

Waste Water Treatment Equipments

- Sludge Dewatering Screw Press

- Multiplate Sludge Dewatering Screw Press

- Industrial Wastewater Treatment Plant

- Chemical Dosing System

- Sludge Dehydrator

- Sludge Dryer

- Dewatering Machine

- Vaccum Eavaporator

- Multi Effect Evaporator

- ATFD

- Dissolved Air Floatation

- Ultra Filtration / Filtration Plant

- Inward Water Drum Filter

- Self-Cleaning filter

Advanced Screw Press Technology for Efficient Sludge Management

At e-Water Mission India Pvt. Ltd., we are very proud to be known as the best manufacturers ofSludge Dewatering Screw Press Manufacturers in India. Our new sludge treatment systems make it easier to get water back and cut down on waste, which helps businesses save money on running costs and follow strict environmental rules.

We design our screw press machines to work the best, need the least amount of maintenance, and last the longest. They also promise that their dewatering will work best on all types of sludge.

Our Knowledge of sludge dewatering screw press manufacturers

e-Water Mission India Pvt. Ltd. is a trustworthy source for screw press sludge dewatering machines. Their products are made to be accurate and flexible.

From municipal wastewater treatment plants to industrial effluent systems, our screw presses can handle a wide range of tasks with the least amount of energy use.

We have the right technology for your needs, from fully automated systems that can run all the time to smaller versions that can fit in tight spaces.

Top 10 Services & Solutions We Offer | Ewatermission

- Industrial Sludge Press Machines

We are an Indian company that makes industrial Sludge Dewatering Screw Press Manufacturers in india and is well-known. Our systems can handle a lot of sludge from textiles, chemicals, pharmaceuticals, food processing, and municipal wastewater treatment.

System for Automatic Screw Press

We make automatic sludge screw presses, so we can sell dewatering systems that don’t need much help from people. Our smart control systems keep an eye on things like energy efficiency, output dryness, and feed uniformity to make sure that our systems always work at their best.

Export Choices for Dewatering Screw Press

We are one of the biggest exporters of dewatering screw presses from India. We sell machines that meet international standards to other countries. We also offer full technical support and the option to make changes to the machines.

Key Features of Our Screw Press Machines

- High solid capture rate and consistent sludge dryness

- Compact design requiring minimal footprint

- Energy-efficient operation with low running costs

- Fully automatic or semi-automatic operation modes

- Simple maintenance and quick installation

- Low operating noise and vibration

- Compatible with polymer dosing systems to increase efficiency

- Corrosion-resistant construction (SS304/SS316 options)

Why Select e-Water Mission India Pvt. Ltd. for Sludge Dewatering?

- Years of experience with sludge management solutions

- Quality Engineering: Use of high-grade materials and precision manufacturing

- Global Reach: Reliable dewatering screw press exporter to overseas customers

- We at e-Water Mission India Pvt. Ltd. turn your sludge management issues into effective, sustainable solutions that produce observable outcomes.

Our Method of Processing | Sludge Dewatering Screw Press Manufacturers

Our end-to-end strategy guarantees hassle-free project execution and long-term performance from site study and tailored design to production, installation, and after-sales servicing.

Sustainable Development

Sludge dewatering press manufacturers lower environmental pollution, carbon footprint, and landfill dependency considerably.

Choosing e-Water Mission India Pvt. Ltd. means working with a business that values environmentally friendly policies and supports a cleaner, more sustainable future.

Contact Us

Are you in search of dependable Sludge Dewatering Screw Press Manufacturers in india, or do you need a sophisticated automatic sludge screw press business for your establishment?

Contact e-Water Mission India Pvt. Ltd., your reliable partner for world-class solutions in sludge management in India and beyond.

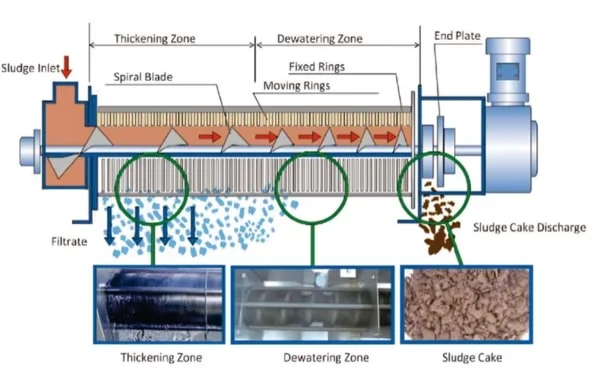

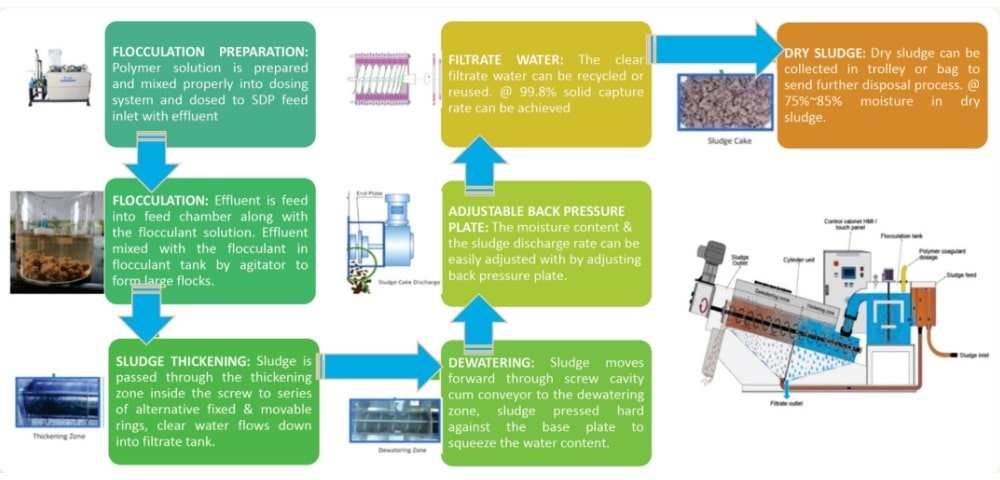

The Sludge Dewatering Screw Press utilizes the dewatering principles of force-water homo-direction, thin-layer dewatering, proper pressure and extension of the sludge dewatering path. The new equipment, more advanced than the traditional dewatering equipment which are easily blocked, unsuitable for low-concentrated sludge and oily sludge, of high consumption and difficult to operate, well eliminate these problems and are of higher efficiency and power saving.

Sludge dewatering press is equipped with unique Technology, which allows dewatering sludge while automatic self-cleaning the filter mesh. This enables stable and constant dewatering without clogging.

The filtering device formed by fixed rings, moving rings, and a spiral in the middle. With screw extrusion principle, strong extrusion pressure generated when the screw diameter and pitch change, tiny gap between the moving ring and the fixing ring to achieve sludge extrusion dehydration.

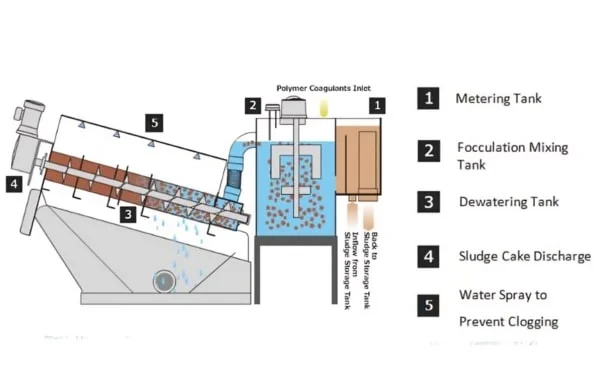

Sludge goes from the feed inlet into the metering tank, moved to the flocculation mixing tank, then moved to the dewatering tank, by the push of the spiral shaft rotary vane, the pitch is gradually reduced, the pressure is increased, the pressure difference makes sludge to be dehydrated, water outflow from fixed rings and moving rings.

The device has self- cleaning function between the fixed rings and the moving rings, and the clearance between the filter and the filter is prevented from being blocked. After sludge is full dehydration, sludge cake is discharged from the discharge port under the action of the propeller shaft.

Clog Free :

With self-cleaning function, clogging is avoided. It can handle oily sludge without any trouble while separating the water from the sludge easily. Also, don’t need large quantity of flushing water, reduce water consumption.

Small Type Design :

It includes electric cabinet, dosing tank,

flocculation mixing tank etc. The

compact appearance takes small space,

easy on repairing, replace and moving.

Operation Easy :

It can operate automatically for 24 hours, unmanned, Daily maintenance is easy and saving time.

Durability :

All parts of the machine is made of 30455, lengthen the using life.

Municipal & Domestic

Textile Tannery Paper & Pulp

Dyeing & Printing

Food & Beverage

Dairy

Agricultural

Petrochemical

Pharmaceutical